Buy corrugated cardboard: with the best from THIMM

Find out everything about the raw materials, the different types of corrugated cardboard, flute types and corrugated cardboard production

Packaging made from corrugated cardboard: A sustainable all-rounder

With THIMM for the optimum packaging solution

Natural and environmentally friendly: We have been producing corrugated cardboard since 1959 and we focus in particular on sustainability. Short transport distances are just as important to us as working with suppliers certified to environmental standards.

What are the benefits of corrugated cardboard?

-

Sustainable recycling product

Corrugated cardboard is mainly made from recycled material.

-

Sustainable from the ground up

Fresh components are obtained from naturally renewable raw materials.

-

Sustainable alternative

Corrugated cardboard can replace plastic packaging in many cases.

-

Ecologically valuable circular product

Corrugated cardboard is still a recyclable material after at least 20 recycling cycles.

-

High acceptance at the POS

The packaging is well received by consumers.

-

Exemplary recycling location in Germany

Corrugated cardboard is almost fully recycled in Germany. The recycling rate for corrugated cardboard is over 95%.

-

Climate-improving base

Trees convert CO2 into oxygen and carbon and are therefore a climate-improving base for corrugated cardboard.

-

Optimised paper cycle

Corrugated cardboard introduces extremely good fibres into the paper cycle.

-

Reduced emissions

CO2e emissions from corrugated cardboard have improved by 11% from 2015 to 2018.

How is corrugated cardboard produced?

THIMM Group

+49 5551 703 0

info@thimm.de

Corrugated cardboard packaging material: The most important points at a glance

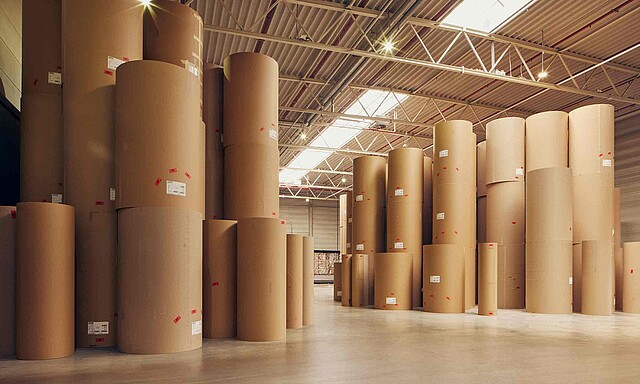

Manufacture: From the raw material to corrugated cardboard

Corrugated cardboard base paper is used as the basic raw material – in Germany it is predominantly made from recycled paper with a proportion of fresh fibres and starch glue. The cardboard is produced in the corrugator and is preprinted or unprinted. This is where the paper rolls are heated and moistened with water vapour. They are then passed through two gear-like, interlocking grooved rollers while pressurised and heated which “iron” the flute into the paper.

Corrugated cardboard production: flexible and adaptable to your needs

Corrugated cardboard can be produced in many different sizes. The different types of corrugated cardboard are based on flute pitch (t) and flute height (h). The designation is based on flute heights and paper grades, grammages and flute pitch. If a roll has run out or if a different paper width or type is to be used, the paper roll is changed in the system. For example, if a new paper grade is to be used, then in the case of a single or multi-flute box the flute profile of the corrugated cardboard is also retained. However, the paper grade is changed, for instance to kraftliner instead of testliner.

Common corrugated cardboard variants: with the best from THIMM

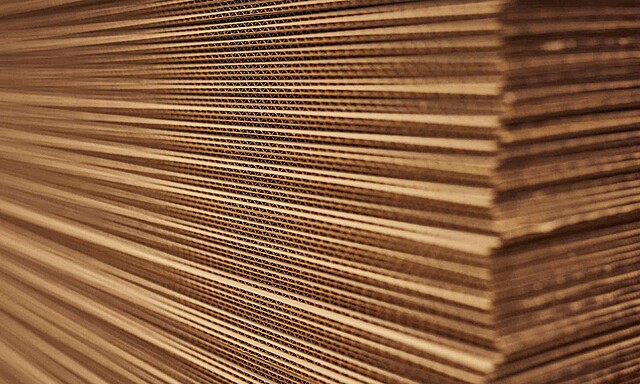

The different types of corrugated cardboard are made up of paper types, grammages, flute pitch and flute height. For example, there are several gradations between F-flute which is particularly fine and delicate and CAA-flute which has a particularly large flute height:

- F-Flute: Flute-height from 0.6 to 0.9 mm

- E-Flute: Flute-height from 1.0 to 1.8 mm

- T-Flute: Flute height of 1.7 mm

- B-Flute: Flute-height from 2.2 to 3.0 mm

- C-Flute: Flute-height from 3.1 to 3.9 mm

- A-Flute: Flute-height from 4.0 to 5.0 mm

- FE-Flute: Flute-height from 1.6 to 2.7 mm

- EE-Flute: Flute-height from 2.7 to 3.2 mm

- BE-Flute/EB-Flute: Flute-height from 3.2 to 4.8 mm

- BC-Flute: Flute-height from 5.3 to 6.9 mm

- CAA-Flute: Flute-height from 11.1 to 13.9 mm

Corrugated cardboard variants: Flexible industrial solutions

The appropriate solution for every need: Single-face corrugated cardboard consists of a cover liner and one flute, single-fluted (e.g. B-flute) from three paper webs. Double-fluted (e.g. BC-flute) or multi-fluted cardboard is also commonly used.

Base paper: The basis for high-quality corrugated cardboard

Paper is the most important raw material for THIMM Group. We print paper rolls from base paper for industrial processing. We also use it to produce corrugated cardboard packaging and corrugated cardboard sheets for every packaging solution. We therefore use different types of paper. The following generally applies to paper selection: The thicker the paper used, the stiffer the subsequent corrugated cardboard vertical to the flute direction. Kraftliner papers, for example, are very strong and stable corrugated cardboard base papers. They consist of at least 80 percent fresh fibres. Testliners, on the other hand, are recycled papers made from 100 percent waste paper. We also offer you innovative solutions: For example, we have introduced two modified paper types based on recycled paper with particularly low grammages. Since 2015 we also have been offering our customers the “Starliner white” paper type which is a fresh fibre substitute which can also enable high-grade printing.

Sustainable corrugated cardboard solutions from THIMM

As an established corrugated cardboard manufacturer, we source roughly three quarters of our base paper from Germany. We purchase the remainder from Scandinavia, Southern and Eastern Europe. Due to our high supply needs we can aggregate these into shiploads and achieve a more environmentally-friendly delivery than by HGV. We source almost all of the base paper for the corrugated cardboard we use for our packaging solutions from suppliers that are certified a minimum to the Controlled Wood or FSC® standard. The benefit for our customers: Complete transparency in the paper supply chain across all processing levels.

Would you like to buy corrugated cardboard or sustainable boxes directly from the manufacturer?

THIMM Verpackung GmbH + Co. KG

+49 5551 703 0

hallo@thimm.de

Corrugated cardboard pre-cuts

Buy all your made-to-measure corrugated cardboard pre-cuts from THIMM: find out here about the different types of corrugated cardboard and flute types, corrugated cardboard production at THIMM and of course about the corrugated cardboard pre-cuts for your own particular purpose.

Always the appropriate corrugated cardboard packaging

The appropriate corrugated cardboard depends on the requirements of the packaging solution. For example, customised packaging for load-bearing heavy electrical devices must be designed differently from packaging for non-load-bearing light crisp bags. As a corrugated cardboard manufacturer with sites throughout Germany, we therefore incorporate all product information and the planned purpose into the selection of the cardboard and the development of the packaging. We would be happy to provide you with comprehensive consultancy and find the best solution for your requirements!