Recyclable packaging in the circular economy

Packaging solutions made from corrugated cardboard: environmentally friendly and sustainable

Closing circles: with sustainable packaging made from corrugated cardboard

Shipping packaging from THIMM: recyclable and made from renewable raw materials

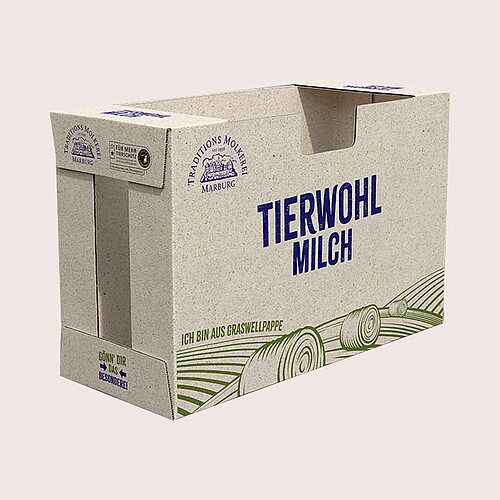

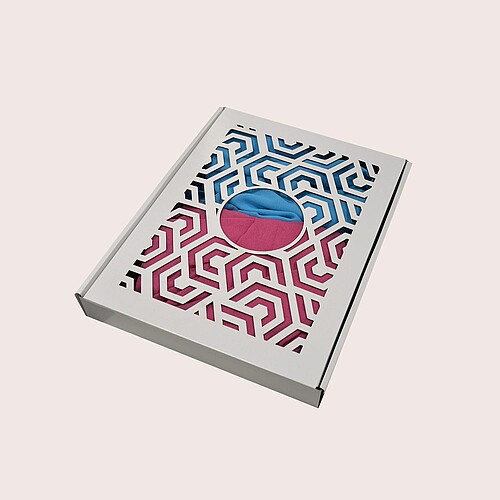

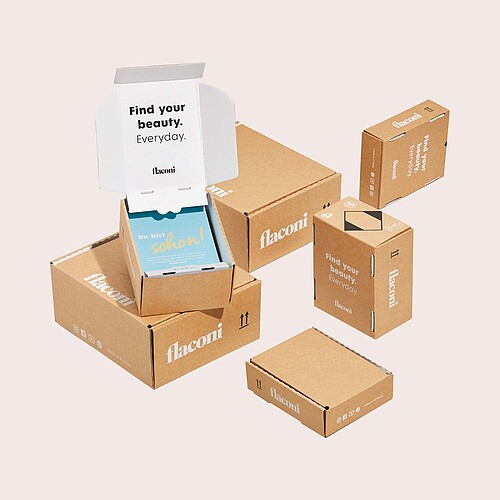

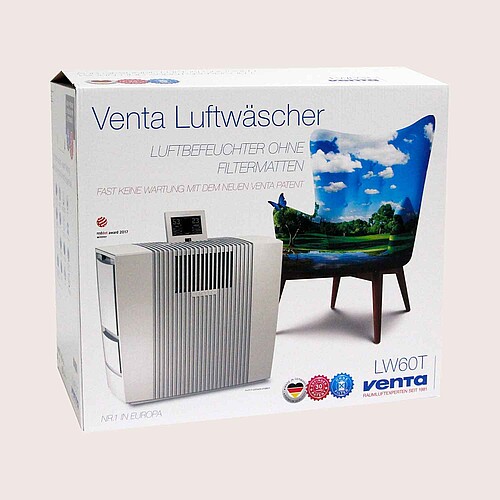

In terms of the circular economy, all processes at THIMM are geared towards conserving resources. That’s why our recyclable packaging is made from corrugated cardboard. Most of our displays are designed using corrugated cardboard and recyclable board. Each packaging unit is a circular product made from naturally renewable raw materials.

From natural raw material to sustainable corrugated cardboard packaging

THIMM turns raw paper into recyclable packaging for food and other consumer goods. The paper rolls are further processed in the corrugator. To do this, the paper is heated and moistened. Under pressure and at higher temperatures, grooved rollers produce the flute sizes required.

Paper: the most important raw material at THIMM

Corrugated cardboard: natural, sustainable, recyclable and resource-efficient

Recycled raw paper is the most important part of the circular economy at THIMM and the base material of recyclable corrugated cardboard packaging. THIMM mainly uses paper that is 100% recycled. For special requirements, we use papers that contain a proportion of fresh fibre.

The differences between corrugated cardboard raw paper types

Our testliners are made from 100% recycled paper. Kraftliners are stable raw papers made of coniferous wood with at least 80% fresh fibres. “Starliner white” is a recycled fibre material with fresh fibre properties that is ideally suited for printing. Special corrugated cardboard made from fresh fibre paper, for foodstuffs for example, complements our range.

The origin of the paper types used at THIMM

About three quarters of the paper we use originate in Germany. We source the other paper we need from Scandinavia and south-eastern Europe. There are also no long transportation routes for distribution and recycling, as the German corrugated cardboard industry is based on regional, medium-sized structures.

Independent procurement of raw materials

THIMM purchases the raw papers for recyclable packaging material made from corrugated cardboard independently. This allows us to access a wide range of materials and create innovative packaging and displays for our customers!

The objective: more recycled paper, less fresh fibre paper

The market for raw paper is constantly evolving. More and more fresh fibre papers are being replaced by products based on recycled paper. Paper surface weights are also constantly reducing. Important steps on our way to more sustainability!

The benefits of corrugated cardboard

-

Recycled material

Corrugated cardboard is mainly produced from recycled paper. Fresh fibre content is obtained from renewable raw materials such as windfall and thinning timber.

-

Good CO₂e footprint

The CO₂e emissions caused by the manufacture and transport of corrugated cardboard packaging have been decreasing for years.

-

High recycling rate

Circular economy par excellence! Corrugated cardboard is almost completely recycled in Germany. According to the VDW, the German Association of Corrugated Board Makers, the return ratio is 80%.

-

High-quality and durable

Even after up to 20 recycling rounds, corrugated cardboard is still a recyclable material with good fibre components and properties.

-

Popular material

Corrugated cardboard has many good properties, is sustainable and robust and is therefore well received by consumers.

-

Replacement for plastic

Due to its specific composition, corrugated cardboard packaging can replace plastic packaging in many cases.

Circular economy in corrugated cardboard production

Recyclability as a top priority at THIMM

THIMM’s sustainable corrugated cardboard packaging is made from renewable raw materials and consists predominantly of recycled fibres. Any additional fresh fibres required are supplied from windfall and thinning timber from sustainable forestry.

The ideal case: a paper fibre with up to 20 life cycles

Waste paper is picked up with deliveries. This means that any production residues are returned to the reusable material cycle. The used packaging is recycled and in turn serves as a raw material for the paper industry. This is a circle that can be repeated up to 20 times.

The legal framework for packaging and packaging waste

The German Packaging Act is the basis for a successful circular economy for sustainable packaging. We have internalised the current laws and guidelines in our processes. Rely on recyclable packaging material and protect the environment!

Recyclable packaging from THIMM

Questions we are often asked about our packaging made from corrugated cardboard

Raw paper is used as the basic raw material for our sustainable corrugated cardboard packaging. This consists largely of recycled paper with a low proportion of fresh fibres. In 2021, the proportion of fresh fibre was only 16 percent. We use almost exclusively water-based glues to manufacture our packaging. Glue consumption has decreased significantly: we used 8,167 tonnes in 2021 compared to the previous year’s consumption of 10,176 tonnes. Our raw paper is 100 percent FSC-certified. It is made from wood that is mainly sourced from sustainable forestry. This means that all of our packaging is environmentally friendly, fully recyclable and a cycle product made from naturally renewable raw materials.

Whereas a cat has nine lives, corrugated cardboard is far more durable, with up to 20 life cycles. When the raw paper is delivered to the plant, waste paper is also taken away. This waste from production and packaging additionally used in the retail sector and private households is thus fed directly into the reusable material cycle. They are recycled and can then be used again as a raw material. Even after 20 recycling rounds, the raw material paper still has excellent fibre properties.

All processes at THIMM are geared towards sustainability. Various measures help to reduce or eliminate waste in production. To reduce the amount of waste, we have, for example, automated the process of shutting down digital printing rolls on the corrugators. The lean process at THIMM also influences the amount of waste. Significant achievements in terms of scrap, performance and set-up times can already be seen here. System downtime is avoided as far as possible. We are also getting closer to our goal of print-on-demand production thanks to economical residual material management and the reduction of overproduction. The amount of production waste has already been significantly reduced.

The raw material paper is precious. We offer our customers a wide range of FSC-certified packaging. The wood for the raw paper comes from ecologically and responsibly managed FSC-certified forests. Our certifications and standards for sustainable and environmentally friendly production also include the ISO 14001 environmental management system and the ISO 50001 energy management system. The topic of sustainability runs through all areas and processes in our company – from the selection and procurement of raw paper to sales.

We source most of the raw paper for the production of our sustainable corrugated cardboard packaging from Germany. As the German corrugated cardboard industry is made up of regional, medium-sized structures, the routes for transport and recycling are short. Other raw paper suppliers of the THIMM Group are located in Scandinavia and southeastern Europe. Due to the high demand for paper (use of raw paper in 2021: 520,002 tonnes), we can aggregate the paper deliveries into shiploads and thus choose a more environmentally friendly mode of transport than by HGV. For our packaging solutions, we source raw paper almost exclusively from suppliers that are certified to the Controlled Wood or FSC standard as a minimum.

We are happy to answer any questions you may have.

Michael Burkowski

Head of Sustainable Packaging Solutions

+49 5551 703 815

michael.burkowski@thimm.de