Trays – sustainable outer packaging made from corrugated cardboard

Trays are an effective sales promotion tool in retail outlets: They are versatile, extremely effective for presenting products and also offer a sustainable packaging solution.

Trays made from corrugated cardboard for retail outlets

What is a tray?

Trays made from corrugated cardboard are sustainable and stable die-cut packaging. Trays are ideally suited for transporting merchandise and presenting it in retail outlets. Their versatility makes them the ideal choice for companies looking for environmental and efficient packaging solutions.

Trays also have another significant benefit: Their height can be flexibly adjusted depending on whether they are self-supporting (e.g. beverage cans) or non-load-bearing products (e.g. crisp bags). Different tray types such as flat trays, stacking edge trays, L-trays and high trays are common in retail outlets.

Their versatile design options enable trays made from corrugated cardboard to be easily integrated into manual, semi-automated and automated packaging lines. Their robust design ensures reliable performance in all packaging processes.

Trays are also referred to as “cartons”.

Benefits of trays

-

Versatile adaptability

Trays are designed with flexibility so they can be adapted to different product sizes and shapes which increases versatility for retailers.

-

Optimum product presentation

Trays are an attractive presentation option for products in the retail sector as they display them in an orderly and very visible manner.

-

Safe transportation

Trays made from corrugated cardboard are a robust packaging solution that ensures product safety during transportation and minimises damage.

-

Boosting brand presence

Custom-designed trays strengthen brand identity and customer loyalty leading to a positive impact on brand perception and sales.

-

Space-saving

Trays are stackable which uses storage and shelf space efficiently.

-

Easy recycling

Trays made from corrugated cardboard can be fully recycled after use and are still a recyclable material after up to 20 recycling cycles.

Trays: Many different types at a glance

The right tray for every requirement

Different tray types are used depending on the requirements and needs of the respective products and packaging applications:

Trays with a stacking edge

Trays with a stacking edge and raised edges provide additional protection for packaged products. These protective edges prevent product slippage during transportation and storage. They also enable the stable stacking of several trays on top of each other which increases efficiency in warehouses and logistics centres. Their robust construction means that trays with a stacking edge are a popular choice for the safe transportation and storage of a wide range of goods.

Trays with stacking lugs

Trays with stacking lugs

Trays with stacking lugs are a practical solution for the safe and stable storage of products. These lugs, often mounted on the side walls of the trays, make it easy to stack several trays on top of each other reliably. Locking the lugs into place prevents the stacked trays from slipping. This not only increases efficiency in the warehouse, but also protects products during transportation. Stacking lugs therefore offer a reliable option for saving space and ensuring tidy storage.

Trays with stacking corners

Trays with stacking corners

This tray with its integrated stacking corners, also called "suspension supports", focuses on product protection. Stacking lugs increase stability in transportation and in retail outlets. By using this tray, up to 15 percent of packaging material can be saved compared to standard packaging, which not only improves sustainability, but also reduces material costs. The tray is suitable for mechanical packaging and can be easily processed with existing packaging technology.

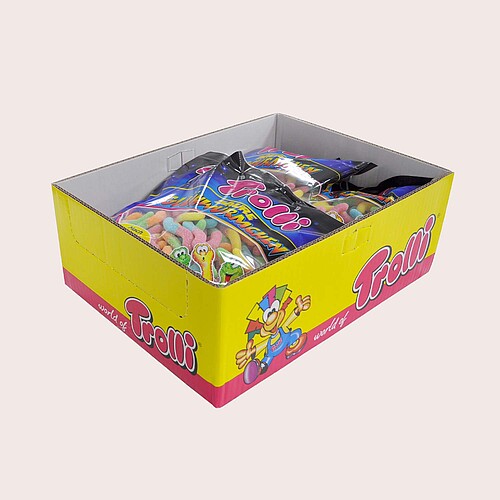

Trays with print

Trays with print

Printed trays are effective sales promotion, they support brand communication and promote brand recognition. A customised design enables companies strengthen their brand identity and build an emotional bond with their customers.

At THIMM we use modern printing technologies to present your brand and showcase your products in the best possible way. Our experienced team of experts will always determine the ideal printing process for your requirements to ensure optimum value for money and convey your brand message effectively.

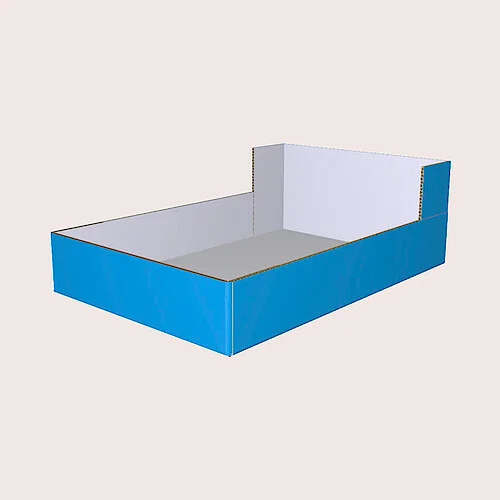

Yoghurt trays

Yoghurt trays

Trays for yoghurts and other dairy products are often referred to as yoghurt trays or yoghurt cartons. Both single-type and mixed tubs can be placed in these trays. The trays are placed in the chiller cabinet making them easy to arrange on the shelf. Customised printing on the trays is also an outstanding tool for sales promotion and orientation on a full shelf. Yoghurt trays also make it easy for consumers to pick up the products.

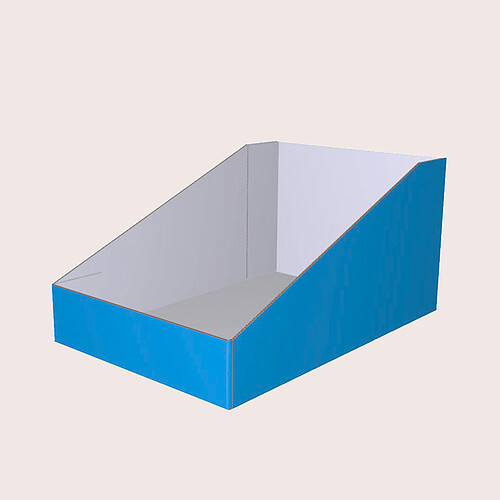

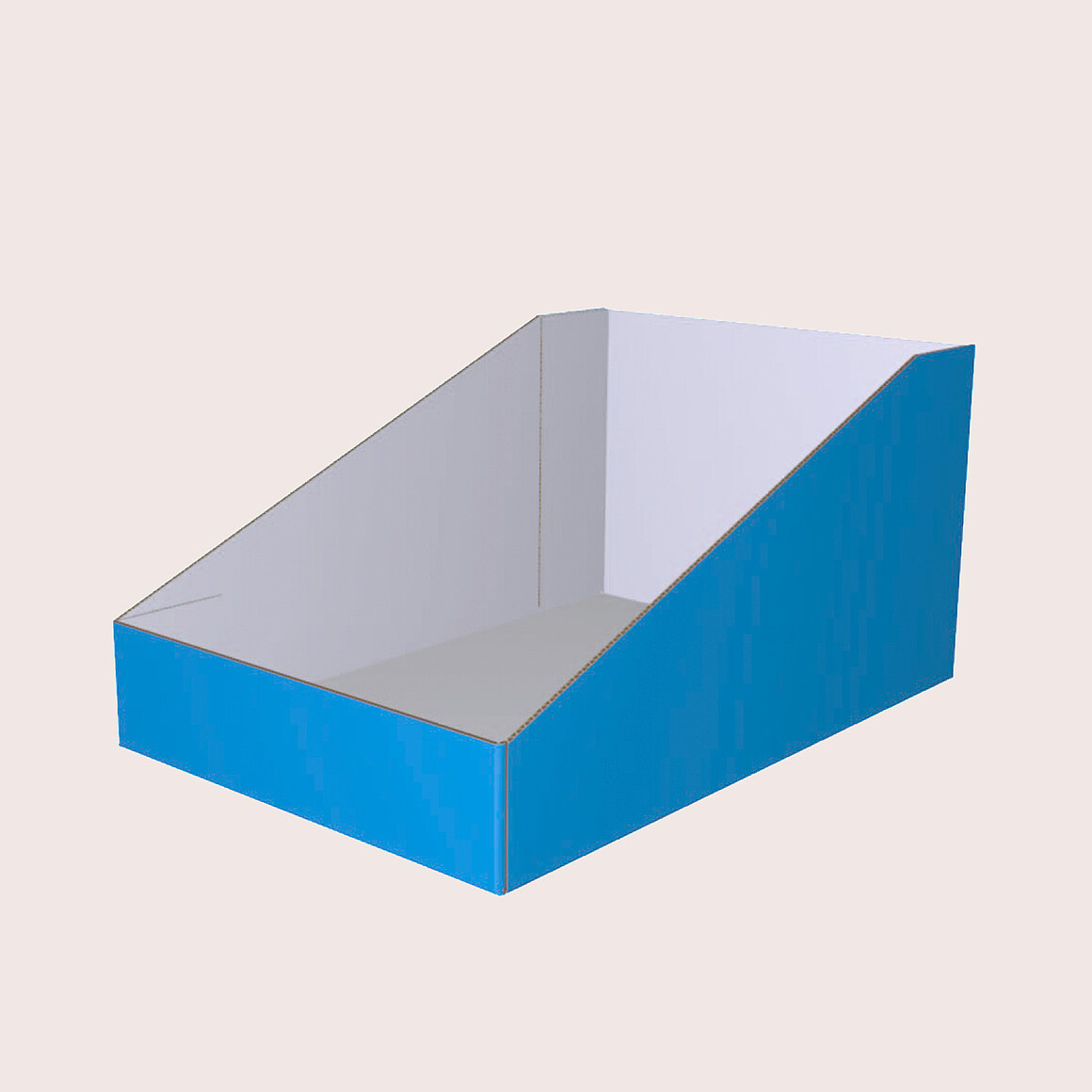

Trays with an integrated step

Tray with an integrated step

Trays with an integrated step are ideal for an optimum presentation over two levels. This is a one-piece tray made from corrugated cardboard. The material-saving tray is 100 percent recyclable. The products are nested inside the tray which ensures the highest possible degree of volume utilisation. The closed sides mean the tray is stable and secure to transport. In retail outlets the tray can be easily broken up using the perforations which ensures an attractive presentation on the shelf or sales counter.

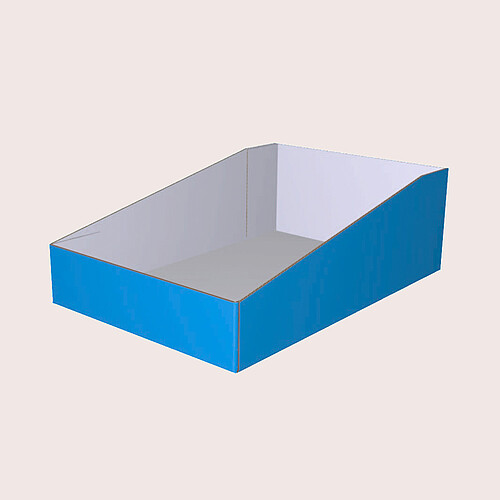

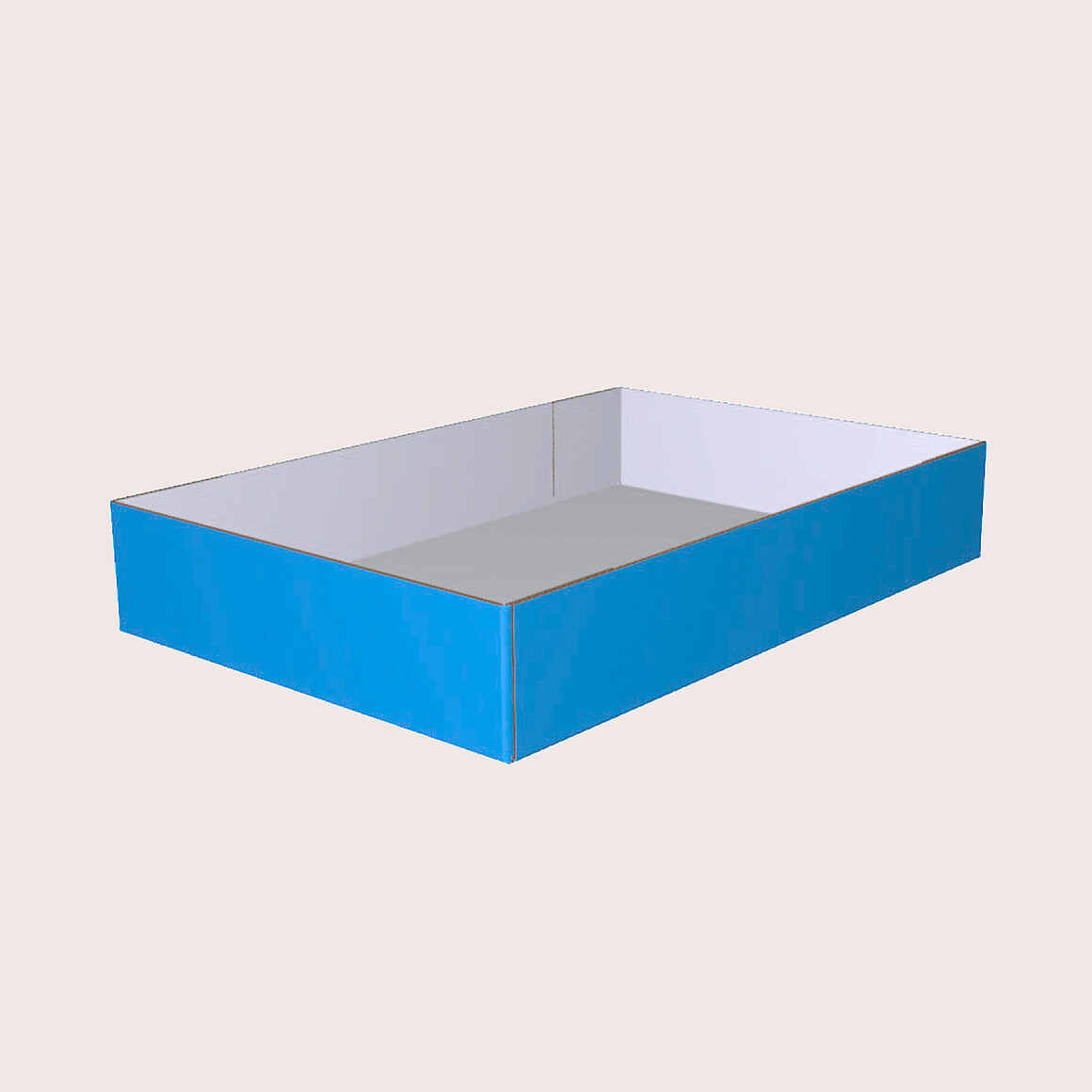

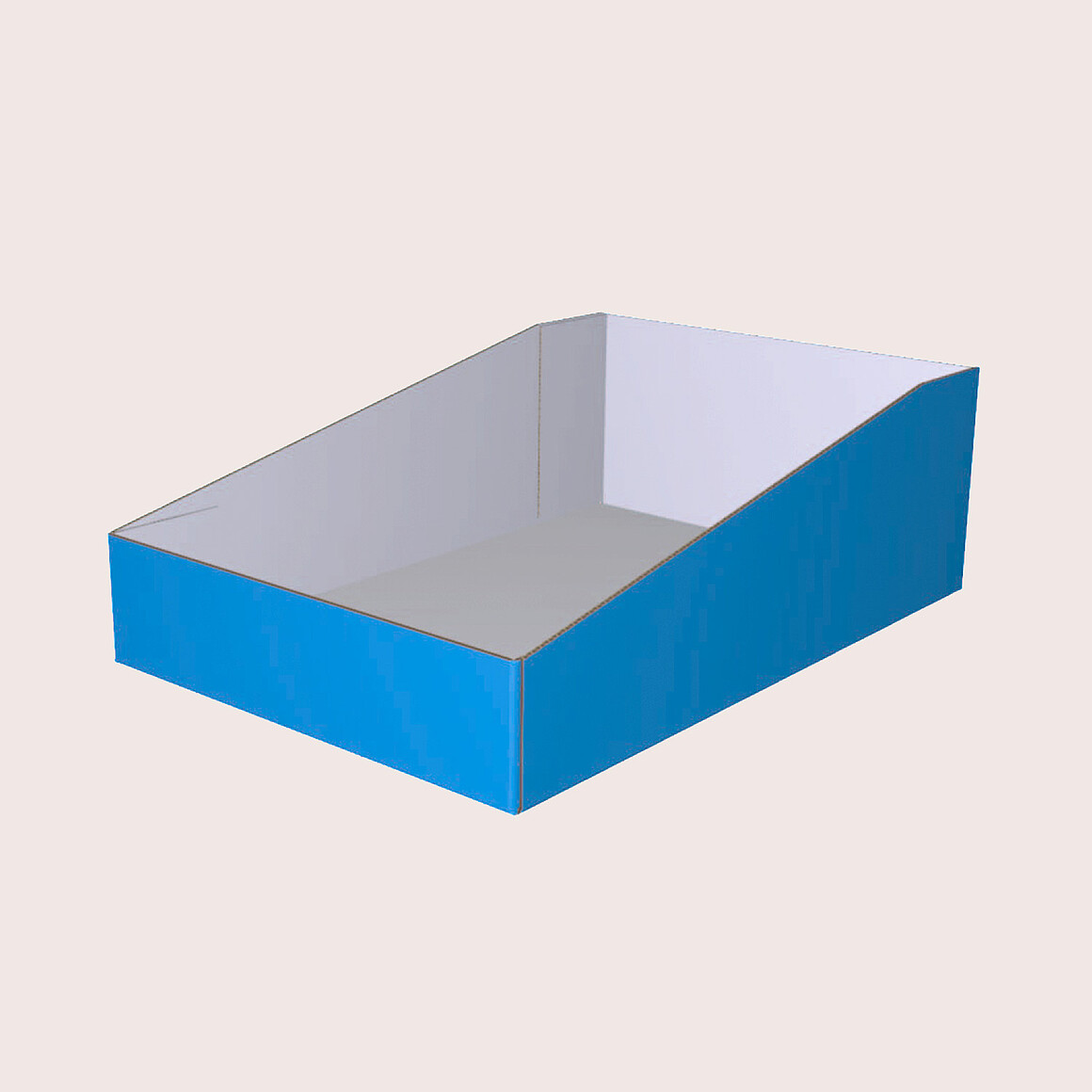

Flat trays

Flat trays

Flat trays made from corrugated cardboard are known for their flat design making them ideal for packaging and transporting larger, load-bearing products such as bottles, jars and cans. Their low height provides a stable base for these items and creates the best possible retail presentation by improving product visibility for customers. Flat trays with lids, sleeves or U-fold-overs are often used as covers to protect products during transportation. With their easy handling and ability to present products in an attractive way, flat trays are a practical solution for storage, transportation and sales promotion. Their versatility means they can be customised to meet the needs of different industry sectors.

Would you like to find out more about trays? Please feel free to contact me!

Michelle Wegener

New Account Specialist

+49 5551 703 0

hallo@thimm.de

Versatility of trays

Trays made from corrugated cardboard are extremely versatile and can be fully adjusted to the properties of the products to be packaged and their intended use. For example, flat trays are ideal for load-bearing products such as cans and jars, whereas high trays with elevated side walls provide additional protection for non-load-bearing products such as sachets and tubes. L-trays and trays with flat facings have variable side heights for any corresponding primary packaging.

Customised adjustments such as stacking edges, stacking corners, stacking lugs and dividers for mixed trays enable even greater versatility and flexibility when using trays.

Packaging Optimisation: Efficient trays for sustainable packaging management

Are you ready to improve your packaging portfolio? Find out how to reduce costs, increase efficiency and implement sustainable solutions! Adaptation of packaging designs to specific requirements is a crucial factor for trays. This may not only lead to savings in packaging material and valuable resources, but also to reduced costs and handling effort.

Flat tray

L-tray

Tray with flat facing elevation

High tray

Sustainable trays: A circular product with a long-term value

Our trays made from corrugated cardboard are sustainable from the ground up as they are made from natural raw materials and mostly from recycled materials. They are 100% recyclable. Corrugated cardboard is still a coveted recyclable material even after at least 20 recycling cycles.