Burger packaging from THIMM: Sustainable fast food solutions

Environmentally friendly burger boxes

Sophisticated packaging solutions for sales and transportation

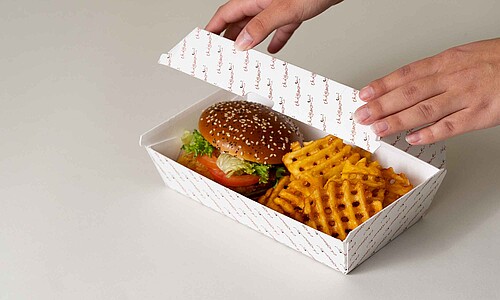

Sustainable and visually attractive packaging of fast food and take-away food: With our high-grade, recyclable cardboard boxes for burgers, including a practical folding lid, food can be packed quickly and transported very easily.

Our packaging for hamburgers: The right choice

-

Recyclable

The used corrugated cardboard can be easily recycled in the wastepaper bin when empty.

-

Plastic-free

Corrugated cardboard consists of natural, renewable raw materials and has a high recycling rate.

-

Coatings

Custom-designed: The cardboard burger boxes can be coated on request.

-

Maximum product visibility

The robust boxes with their practical folding lid mean that food can be transported safely.

-

foodWave®

The special corrugated cardboard ensures 100 percent safe direct food contact.

-

ISEGA certified

Upon request, you receive a certificate and declaration of conformity for foodWave® products.

Would you like to know more about our burger packaging?

Andre Kuhlmann

Senior Product Manager

+49 175 8768336

hallo@thimm.de

Innovative fast food packaging from THIMM

Replace plastic with foodWave®

Store and transport burgers safely and hygienically in the packaging: Our foodWave® is ideal for direct food contact – of course the food packaging is mineral oil-free and produced according to BRC standards.

Service & consultancy

Consulting, development, packaging design: At THIMM everything comes from a single source

Sustainability

Smart, sustainable and recyclable packaging saves resources

Digitalisation

We are working on the Internet of Packs and on the digitalisation of the entire supply chain.

Certificates

Quality, energy and environmental management: THIMM is multi-certified.

Customised and modern packaging for burgers: We would be happy to advise you!

Just call us!This is what we are often asked about our burger packaging

We produce our burger packaging from corrugated cardboard. This is because of its many positive properties. It is made of certified paper produced from 100% fresh fibres and is therefore safe for contact with food and meets all specifications. Corrugated cardboard completes the circular economy perfectly. Today, corrugated cardboard is often seen as an environmentally friendly alternative to plastic packaging – ideally suited to sustainable fast food packaging!

We offer all current high-quality printing processes – digital printing as well as offset printing and flexo printing. Give your packaging solutions a distinctive design with custom printing!

Thanks to two innovations, our sustainable burger packaging is absolutely safe and suitable for direct food contact. Our certified food packaging is made from foodWave® corrugated cardboard. Burgers are best packed in foodWave® packaging in combination with our special coating, as this makes the packaging oil- and grease-repellent. Another way to package moist and oily foods such as burgers in a safe and environmentally friendly way is to use a packaging solution with our ComBa® coating. This coating is the perfect addition to food packaging and is an environmentally friendly alternative to plastic or conventional film coatings. Always sustainable: of course, all our burger packaging can be easily disposed of with waste paper when emptied completely, and then recycled.

Fast food packaging that reliably protects greasy or hot food while being sustainable: our burger packaging made from corrugated cardboard is an environmentally friendly alternative to plastic. With the help of similarly environmentally friendly coatings, it is ideally suited to direct food contact and meets even the most stringent hygiene standards.

Of course, we hold all the important certifications in the field of packaging. In the area of food safety, this is the BRC Global Standard (Brand Reputation through Compliance). This certificate is valid worldwide and defines the quality and safety requirements for packaging and the materials used for it. The certification includes very specific requirements in the areas of quality, hygiene and product safety and is ideally suited to communicate the high quality and safety of packaging solutions for direct food contact to your customers.

Yes, our packaging developers can design prototypes. To do this, they first create drawings using state-of-the-art CAD software solutions, which form the basis for the prototype. Our next work step – testing the planned product for durability – only takes place after your thorough inspection and approval. This way, you always have full control and make all the decisions about your customised packaging solution!