Digital laser cutting

Digital laser cutting opens up new creative possibilities for designers! Lasers are able to cut designs made out of corrugated cardboard which previously could only be produced with difficulty, or not at all. THIMM is using a Highcon digital laser cutter for the production of packaging, displays and decorative backdrops, which thanks to its specific laser technology cuts and engraves with absolute precision. The creases are created by the patented DART (Digital Adhesive Rule Technology) technology. The entire work process from design through to production is digital and it is flexible, reliable and fast. Cutting dies that we know from rotation and flat punching technologies, are not required.

Aus gewöhnlichen braunen Kartons werden dank Laserstanzung Verkaufsverpackungen, die nicht zu übersehen sind (Foto ©Highcon)

For what purposes is digital laser cutting suitable?

- To increase the sales of your products

- For exclusive gift packaging

- For designs with a lot of openings or filigree cutting outlines for which production is not possible on analogue punching machines or where the tool-making would be too expensive

- For packaging with reliable and clean tear perforations

- For small print-runs and one-off test orders because the digital laser cutting technology removes any concerns about the often higher costs for cutting tools

Personalisierte Verpackung mit gelasertem Namen

- For packaging, displays and decorative backdrops which have to be produced and delivered quickly

- It is ideal for customised packaging on which you can cut the name or logo of your customer using digital laser cutting

- As a unique packaging identifier for counterfeit protection

- To highlight items in the sales outlet since packaging optimised with digital laser cutting is guaranteed to be noticed by your customers at the POS

- For products which stand out from the competition as you are amongst the first to use packaging which has been cut with a digitally controlled laser

Digital printing and digital laser die-cutting

Digital printing in combination with digital laser cutting gives your products unique exclusivity.

In Kombination mit dem Druck lassen sich mit einer digitalen Laserstanzung tolle optische Effekte erzielen (Foto ©Pringraf)

The combination of different colours and the layering of different punch motifs create unique and totally customised packaging, displays and decorative backdrops. Sophisticated packaging enhances product value from a visual perspective and also unconsciously bestows a higher-quality impact to your products. Consumers are prepared to pay a higher price for an exclusively packaged item.

Each individual packaging unit for your products can be printed individually and furnished with a customised punched decorative motif. Your customers can therefore choose their own variants – they will be excited!

Eine lasergeschnittene Umverpackung über einer farbigen Primärverpackung (Foto ©Highcon)

The striking laser-cut motif creates exclusive gift packaging from a simple packing box.

A single-colour outer cover over the colourful primary packaging gives the packaging a new optical dimension and the merchandise a more luxurious impact.

More flexibility for your creative designs.

The creativity of your designs is now limitless as cutting tools are no longer required. Thanks to digital production technologies you can not only easily modify the print design but also adjust the cutting shape in any way you choose. In contrast to traditional punching processes for which cutting tools first have to be made and which cannot be changed subsequently, in digital laser cutting any last minute corrections can be made at any time prior to production. When using laser cutting only the digital data of the drawing have to be modified.

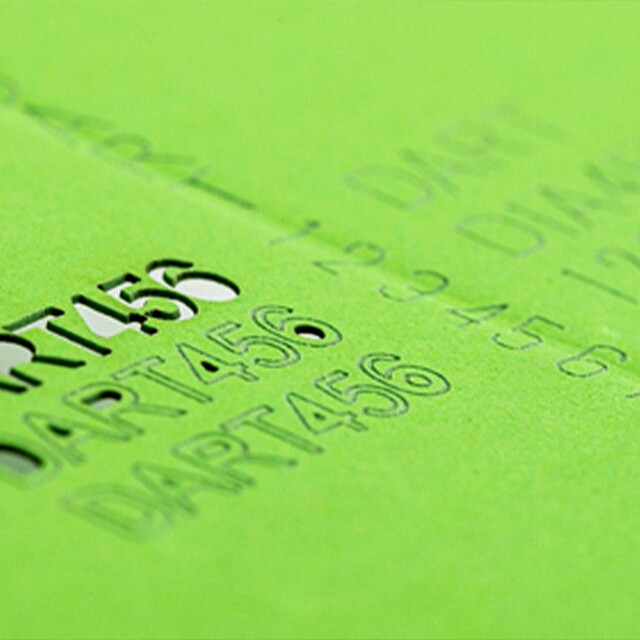

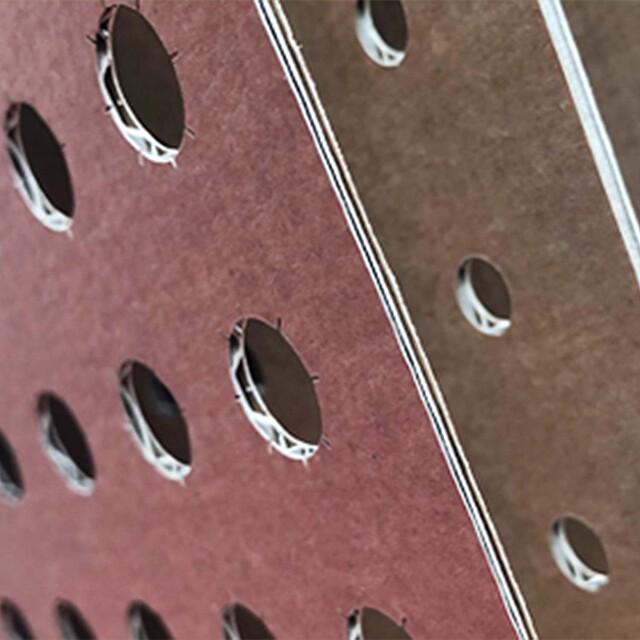

Unterschiedliche Perforationen, die mittels Laserschnitt gefertigt wurden (Foto ©Highcon)

Your packaging will open easily and cleanly thanks to the precision perforations.

So that packaging can be opened easily and quickly, tear perforations are incorporated into the design development. How the packaging looks after the perforated area has been torn off depends on the quality of the design.

Unfortunately when unpacking merchandise in retail outlets on-site staff tend not to pay too much attention to the ultimate appearance of the packaging. They have to open the packaging as quickly as possible and arrange it on the shelf. But with digital laser cutting very delicate perforations can be created which are easy, fast and clean to open.

Eine mit Laser erstellte Perforation funktioniert zuverlässig (Foto ©Highcon)

Goods displayed in retail outlets where the packaging has been opened badly due to a poorly designed tear perforation often look like second-class goods at the POS. Product and brand image then suffer in the eyes of consumers.

The situation is similar for shipping packaging. By integrating a perforation into a shipping packaging unit, eShops can help their customers gain access to their ordered goods more quickly. The easier it is to open a packaging unit, the better the unboxing experience for the customer.

Digital laser cutting with its precision perforations enables packaging to be opened easily and cleanly in retail outlets or upon delivery of a consignment – without any tools or damage to the packaging.

Counterfeit protection: Identification of packaging with a unique laser code

Digital laser technology can also be used to combat counterfeits. Cut codes can complement protection elements printed on the packaging or even replace them. With the laser, symbols, figures, letters, etc. can be burnt (cut-out) or engraved (cut-in) in the corrugated cardboard packaging. Each packaging unit can be given its own unique code which proves the authenticity of the goods.

Lasering in combination with the patented DART technology also enables engravings or cuts in the bend points (creases) of the packaging and even in one single work step.

What you see is what you get

Samples of packaging or displays which were produced using digital laser technology on a Highcon machine also have the benefit that they correspond exactly in appearance and design to the products that you will then order from us in larger quantities.

Everything is produced on the same machine, whether it is a one-off piece, a small print-run or a large order. Unlike a test sample cut with the plotter, the same data are used here. Therefore, faulty or imprecise data conversion is excluded. You can be certain that, on the basis of the sample, you will actually get what you ordered.

Would you like to test which motif has the best level of acceptance by your customers and is the most frequently purchased? Thanks to digital laser technology you do not need to invest in different cutting tools and you can still test all your designs. You will then only order a larger quantity of the version that you really need.

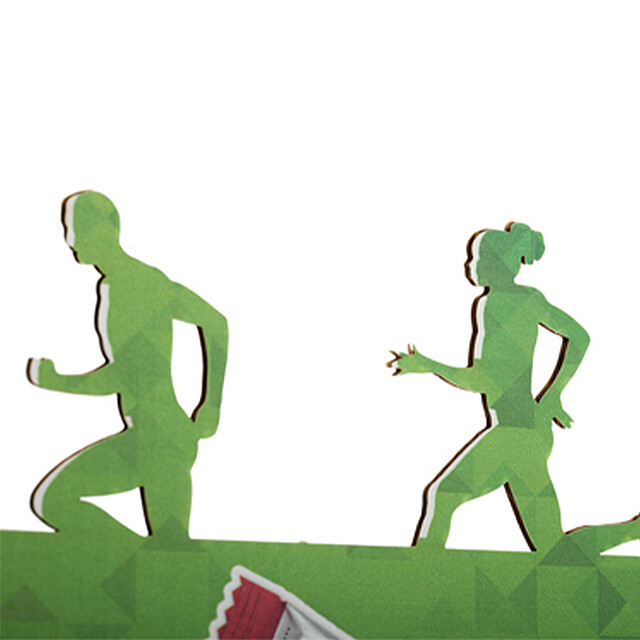

New design possibilities: filigree outlines and numerous small openings

The production of packaging designs made from corrugated cardboard is based on the limits of rotation and flat-bed punchers. Digital laser cutting overcomes these limits and expands the possibilities for the production of packaging, displays and decorative backdrops

For product fixings used to lock goods in place (e.g. tubes of creams, lipsticks, etc.) in sales packaging or displays, previously the high costs for cutting tools had to be taken into account. The more complicated the cutting, the more expensive the tools. Digital laser cutting reduces these costs to a minimum.

Foto ©Highcon

It is impossible to cut curves or very delicate outlines with traditional cutting technologies (rotation and flat-bed punchers). Using the laser and also at very high speed, very small openings and acute angles can be cut and even when a large number of openings is planned for.

The most delicate outlines of curves can be easily cut with the laser. The laser leaves no fray behind and the end product is processed cleanly.

Digital laser technology also contributes positively to sustainability.

This is because a digital laser cutter only produces the precise number of items you have ordered. No surpluses are produced as is the case when running/stopping conventional cutters. This creates savings in the materials and energy required for the material production and also reduces transportation volumes.

Do you have questions about digital laser punching?

Dann melden Sie sich gerne bei uns:

THIMM Group

+49 5551 703 0

mail@thimm.de